The $5.8 billion vehicle battery production plant Ford and SK Innovation plan to crank up in 2025 just south of Elizabethtown is an economic meteor with an impact expected to ripple across Kentucky for decades.

The $5.8 billion vehicle battery production plant Ford and SK Innovation plan to crank up in 2025 just south of Elizabethtown is an economic meteor with an impact expected to ripple across Kentucky for decades.

“It is a game changer and it is planetary in scope because it has its own gravity that’s going to pull in so many other companies,” Gov. Andy Beshear said.

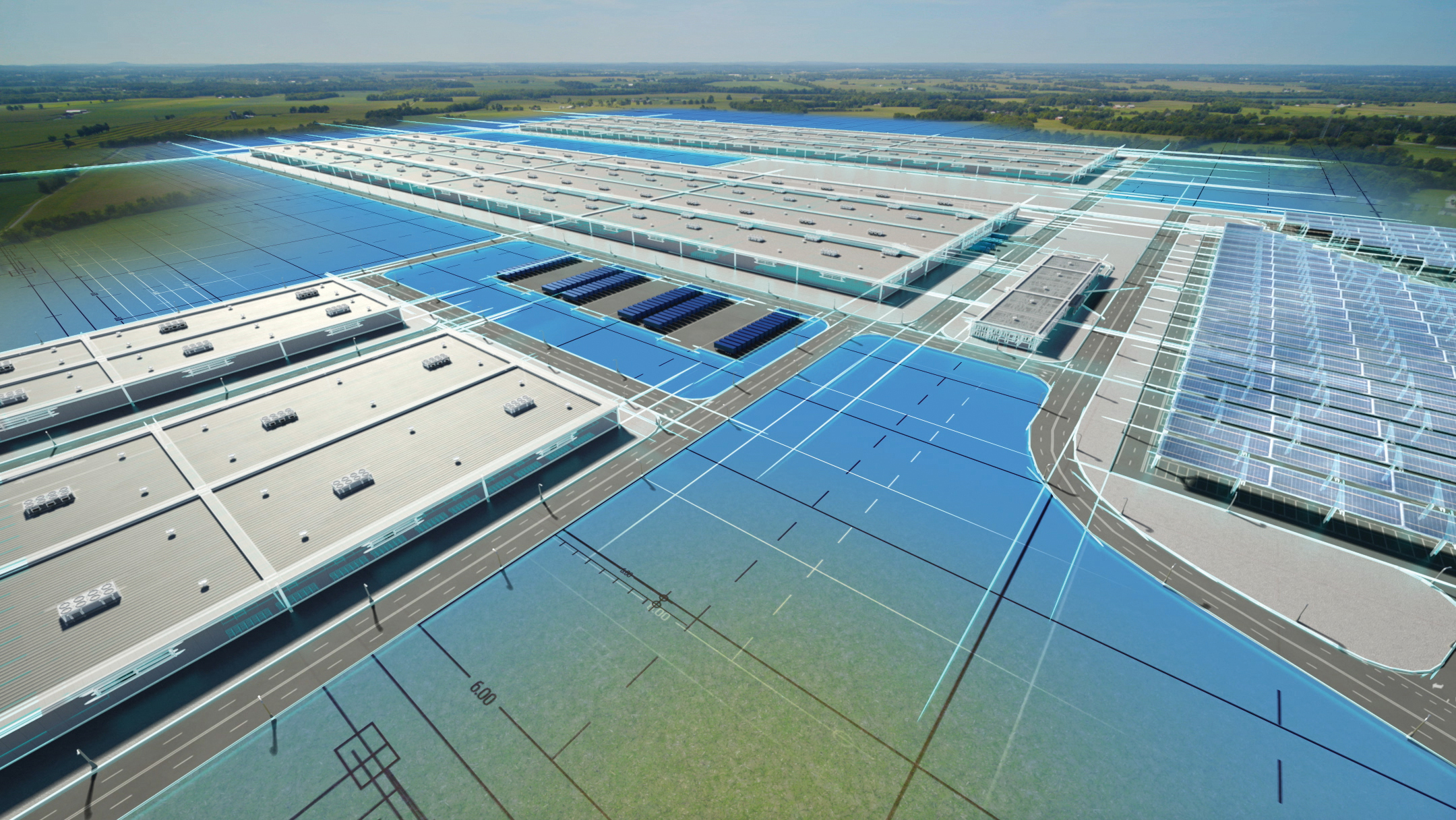

The coming twin side-by-side plants capable of providing 86 gigawatt hours of power annually are a project more than triple the cost of any past Kentucky development. They will add 5,000 Ford employees to the 13,000 now at its two vehicle assembly operations in Louisville.

Current information, Beshear said, calls for batteries to come off the assembly line at the first plant in 2025 and the second in 2026. They will supply “generations” of vehicles, said Ford Executive Chairman Bill Ford Jr., who describes the undertaking as the most significant advancement in the auto industry since the Model T.

Financially, the 1,500-acre campus in Hardin County is the larger half of the biggest investment in the history of Ford, which ranks No. 9 on the Fortune 500. Ford and SK also will churn out another 43-gigawatt hours of batteries annually and make F-150E Ford pickups near Memphis.

“And who are they trusting with the biggest advancement in the auto industry since the Model T?” Beshear said. “The people of the Commonwealth of Kentucky.

“Landing the project has made us the talk of every boardroom across the United States, and every country in the world now knows not just where we are but what we can do,” he said. “But the actual operation of taking this project and getting it done is going to be that crowning jewel. Then we can talk to anybody else betting their company with a project of any size, and they’re going to know this is where they should be.”

While several thousand construction workers are transforming southern Hardin County over the next four years, Beshear said, the state will apply all available resources to create the “best custom solution” to meet Ford’s workforce needs.

The BlueOvalSK operation coming to Kentucky will require a new supply chain to provide materials and components, and this might bring an additional nine or 10 figures in dollar investment and thousands more jobs.

Kentucky’s existing manufacturing industry is getting excited to learn what components the battery plants will need, said Melissa Aguilar-Southard, director of member relations with the Kentucky Association of Manufacturers (KAM).

“Current (KAM) members are already asking about how to get on the wagon to work with them,” Aguilar-Southard said. “We really haven’t heard about the suppliers that need to be attached to the company.”

That remains an unknown at this point.

Meanwhile, the mining industry also sees opportunity because battery-powered vehicles and a more electrified economy require rare earths and critical minerals, said Rich Nolan, president of the National Mining Association, which has seven Kentucky members.

There is “an impressive outlook” for metals, rare earths and critical minerals for EVs and their batteries, Nolan said. The list includes copper, lithium, nickel, manganese, cobalt, graphite, chromium, molybdenum, and smaller amounts of rare earths neodymium, praseodymium, dysprosium and terbium, and others.

“The demand forecast for these is expected to skyrocket,” he said. The industry alerted immediately when Ford CEO Jim Farley said the company’s battery and EV supply chain “has to go all the way to the mines.”

China is the main source of rare earths today, but Forbes reports USA Rare Earths is developing a mine in Texas it hopes will produce rare earths and critical minerals required for EVs and renewable energy production. The hope in Kentucky is that demand for coal-mining skills will rebound since rare earths can be associated with coal-bearing deposits.

China is the main source of rare earths today, but Forbes reports USA Rare Earths is developing a mine in Texas it hopes will produce rare earths and critical minerals required for EVs and renewable energy production. The hope in Kentucky is that demand for coal-mining skills will rebound since rare earths can be associated with coal-bearing deposits.

The U.S. currently does not know its mining potential for these materials, Nolan said, but there is money in the $1.2 trillion federal infrastructure bill for a national “mapping” project — core samples will be drilled in prospective geologies, including Kentucky’s coal fields. While mapping identifies developable deposits, he said, the industry is working to address another problem: It takes an average of 10 years to obtain a permit for a new mine.

U.S. Rep. Andy Barr, whose Kentucky 6th District includes mining interests, served on a special House China Task Force that identified concerns that China is seeking control of massive undeveloped lithium resources in Afghanistan.

“That is why I introduced legislation to streamline the permitting process for coal projects that mine rare earth elements and critical minerals,” Barr said. “We cannot successfully transition to electric vehicles or support new battery jobs in Kentucky while continuing to depend on China for rare earth minerals needed to produce these batteries.”

In announcing its $11.2 billion EV and battery technology play, Ford said it is investing $525 million during the next five years to transform America’s auto technician industry. Some $90 million will be spent in Texas, but there are no specifics for where the other $435 million will land.

Its investment will go toward job training and career readiness initiatives for the current and next generation of technicians to support Ford’s growing portfolio of connected electric vehicles.

Meanwhile, KAM is about to unveil a “Be Pro Be Proud” initiative to inform Kentucky students about trade positions by giving them a taste of virtual on-the-job experience. In planning since 2020, its key element will be a semitruck whose trailer is built out with a dozen immersive VR work stations where students can experience driving a dozer, welding, chemical industry processes, a vehicle manufacturing work station and more.

“It will represent our most widely needed occupations that are open,” Aguilar-Southard said.

The timing turns out to be even better than expected for “Be Pro Be Proud,” which aims to build interest in manufacturing and related jobs, she said. The demonstration unit will travel from school to school around the state and provide those about to enter the workforce with details on the skills and preparation required.

Beshear said his administration believes it is making headway to position Kentucky to “truly be a leader in the technologies of tomorrow” with success in recruiting and growing companies, jobs and training.

“‘What our hope would be,” Aguilar-Southard of KAM said, “would be for us to look internally in the state for what suppliers are here already that can expand their operations” to build the BlueOvalSK supply chain. KAM members “are champing at the bit to get in the door to have those conversations about what they can do.”

Energy utilities have made no announcements of projects that attach specifically to the battery plant project, which is expected to go into active construction in 2022. There is general discussion in the public and private sectors, though, about the need to add EV charging stations all over the state.

In early November, Ford said a research alliance it has with the Purdue University College of Engineering is yielding advances in cable technology that will enable rapid recharging of EV batteries—as fast as a fill-up for today’s gasoline vehicles. The Purdue partnership is addressing the problem of cable overheating from carrying large volumes of electricity.